Projects

MPI Interim Quarantine Facility

Client

- Ministry for Primary Industries

Project Leads

Sector

Location

- Auckland – Northland

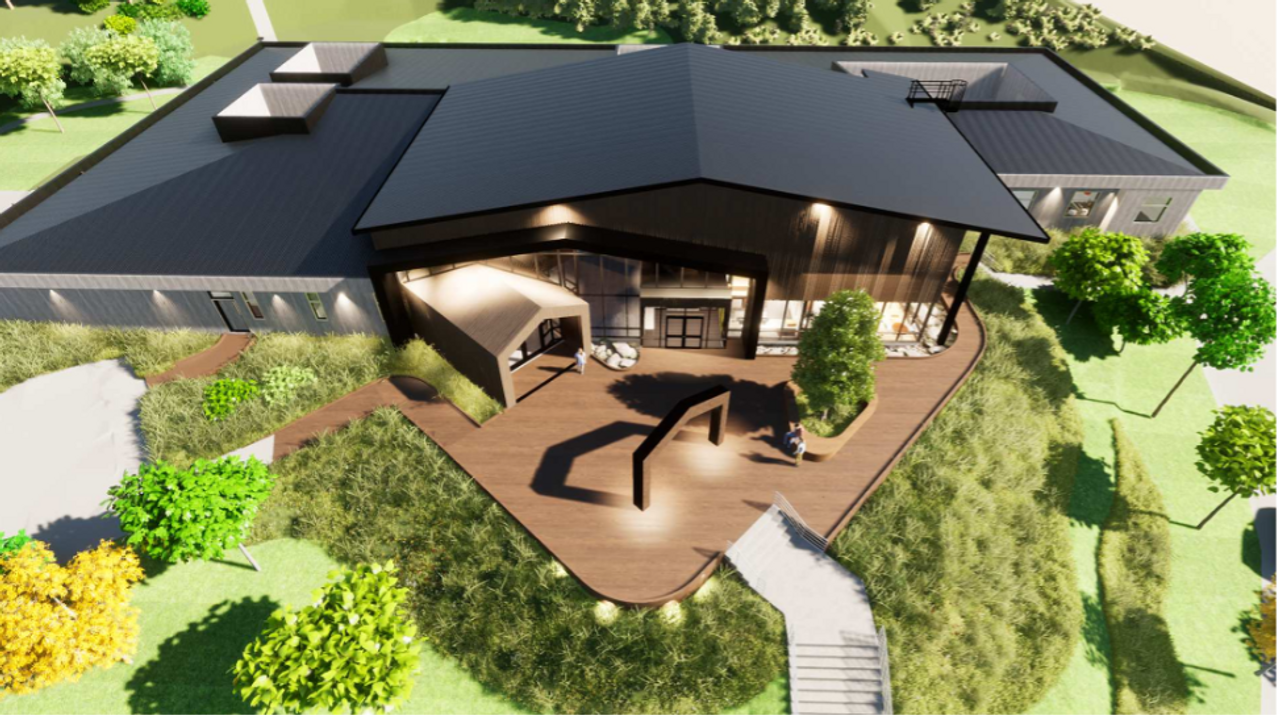

The establishment of an interim quarantine biocontainment facility for plant products signifies a major endeavour for the Ministry for Primary Industries (MPI). Vital for protecting the country’s horticultural sector from potential biological threats, the project arose from the need to replace an outdated quarantine setup near a university campus, which no longer met the growing demands.

The facility's seven-year lifecycle before transitioning to a permanent, larger facility reflects MPI's forward-thinking approach. The future facility is expected to have more greenhouses and greater capacity, addressing the growing needs of New Zealand's horticultural sector. In the interim, the current facility serves as a crucial component of MPI's strategy to protect the local ecosystem while supporting research and commercial activities.

As project managers, RCP’s responsibilities included project establishment, design process coordination with the lead consultant, contractor procurement, contract administration and delivery management.

The interim facility is notable for its complexity and specialized nature and a key challenge was adhering to the stringent L3B biocontainment standard. The facility comprises 12 greenhouses and a head house with laboratories and support facilities, operating under negative pressure to contain potential toxins, insects, or microbiological inclusions.

Implementing value management strategies to reduce costs without compromising the facility's functionality required a delicate balance between maintaining high biocontainment standards and managing financial limitations. The phased construction approach allowed for continuous adjustments, ensuring the project remained on track despite hurdles.

Managing procurement and budget issues was a critical aspect of RCP's role. The competitive construction market in 2021-2022, combined with resource shortages, posed significant challenges. Skilled workers were often engaged in higher-value projects, making it difficult for RCP to secure necessary resources, leading to complex procurement strategies and inevitable delays.

Coordination and management complexities further added to the project's challenges. RCP ensured seamless communication and collaboration among various architects and design consultants. The need for specialised accreditation from experts, many based in Australia, underscored the intricate demands of constructing a biocontainment facility. These accreditors were involved from the design stages through construction, ensuring compliance with all necessary standards.

RCP's experience in similar projects, such as PC-3 labs for medical virus containment, was valuable and the team’s advice on selecting reliable subcontractors and commissioning teams was instrumental in overcoming various hurdles. The emphasis on quality over cost-saving measures was also critical, as any compromise would have rendered the facility unusable.

The facility's completion in February 2024 marked a significant milestone. With MPI conducting trial runs and internal testing, the facility is poised to start commercial operations. This phase involves housing plant products for clients who will pay MPI for the quarantine services, ensuring a controlled and safe introduction of these products into the local market.